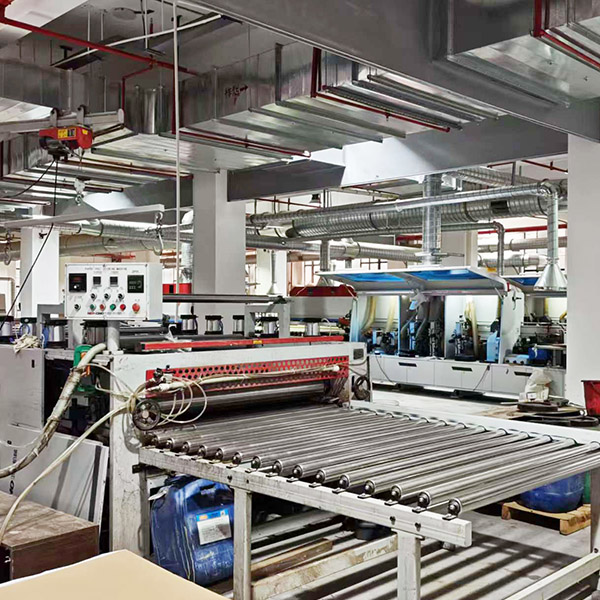

Continuous Equipment Innovation

Since commencing production, Zhangzhou Boyao Industrial & Trade Co., Ltd. has consistently upgraded its machinery, including advanced edge banding machines, engraving systems, CNC six-sided drills, and dust-free workshop facilities. These innovations enhance production efficiency, product precision, and design versatility to meet diverse market demands.

Rigorous Quality Assurance

Every panel undergoes thorough pre-production inspection, burr removal, and post-production assembly testing. An independent quality control team conducts random sampling, drop-resistance checks, and customer-perspective evaluations, reporting directly to the CEO to ensure impartiality and high standards.

Smart Inventory Management

A dedicated 2,000-square-meter warehouse employs advanced supply chain software for precise inventory categorization, safety stock optimization, and quality-preserving storage solutions, ensuring seamless material flow and product integrity.

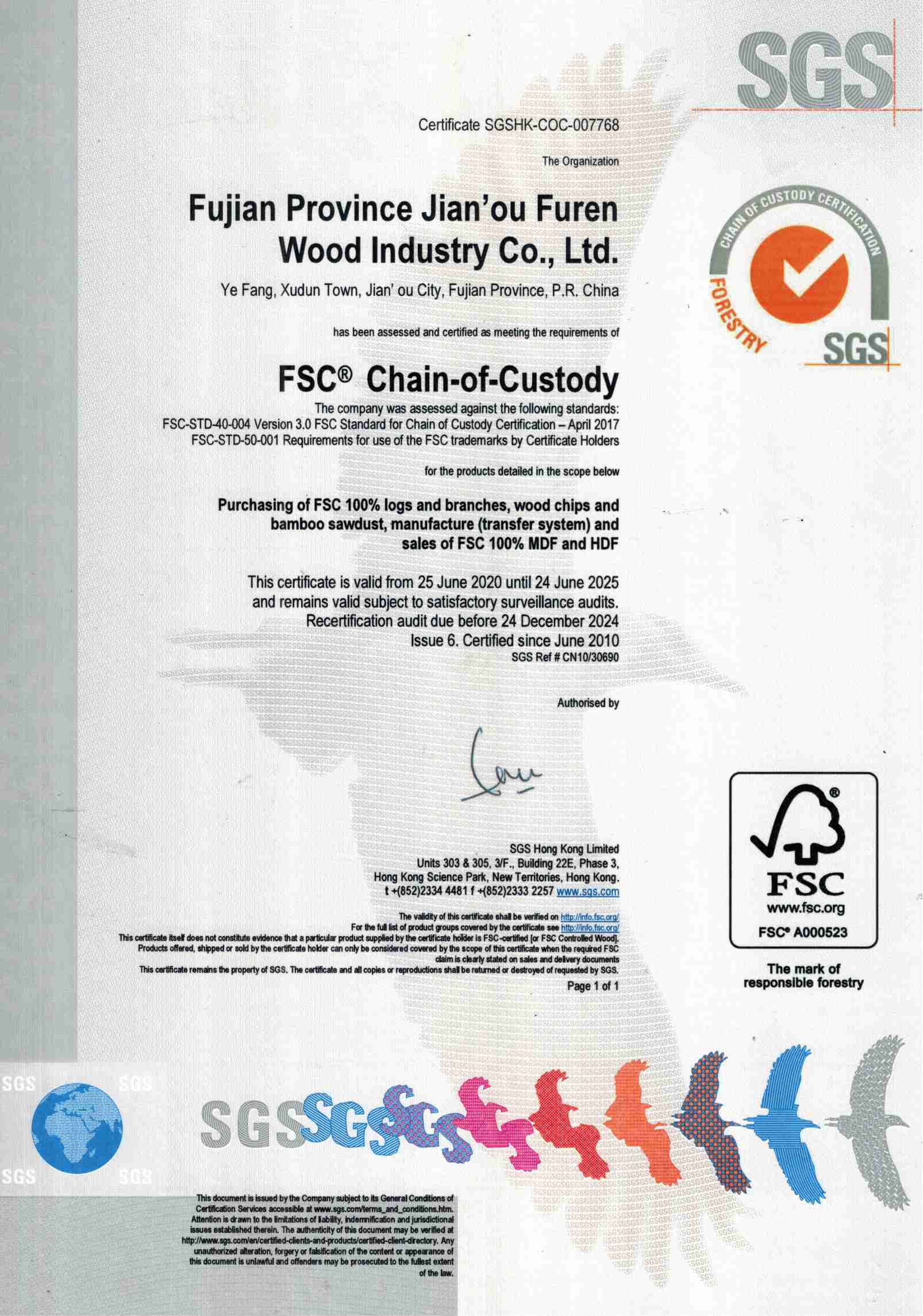

Eco-Conscious Material Sourcing

Strict adherence to FSC 100% certification guarantees the use of sustainable logs, bamboo sawdust, and wood chips in manufacturing FSC-certified MDF/HDF boards, prioritizing consumer safety and environmental responsibility.

Post-Production Validation

All products undergo functional assembly tests to verify durability and usability, ensuring flawless delivery and customer satisfaction.

Sustainable Operations

The factory prioritizes worker well-being by minimizing wood dust pollution and fostering a safe workplace. Balancing productivity with employee health, the company upholds a philosophy of steady, eco-aligned growth.